The idea behind a brake master cylinder brace is to contain the amount of firewall flex that is experienced under braking, and thereby reduce the corresponding movement of the cylinder itself and increase the pedal feel. The RX-7, especially given its lightweight construction, is susceptible to this kind of flexing in the firewall.

A rotary specialty shop on the East Coast named IRPerformance devised a billet aluminum and hard anodized brace as a solution for LHD cars. I jumped on the group buy that was started for this brace at the beginning of this year… and only got around to installing it now. To give perspective of the time, the initial sign up through the delayed manufacturing and ultimately to the delivery of the brace required the passing of 8 months. I held off on the install for an additional month because the original stopper was incompatible with the larger 929 master cylinder that I have. IRP eventually sent me a slimmer, fixed-style stopper.

It was a lengthy wait for a relatively simple product, but that is how these things sometimes go. The bottom line is, we are lucky that there are shops like IRP still developing new parts for this chassis, because I’m sure the margins aren’t enormous for such a niche market. It’s a double edged sword that makes it hard to complain.

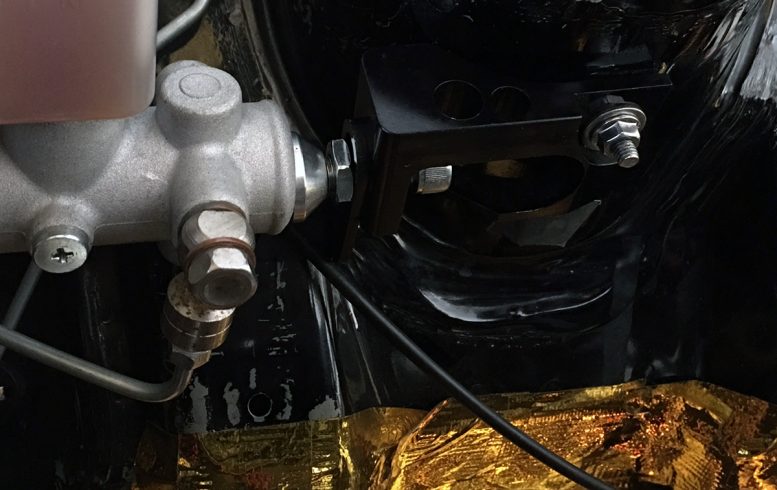

The brace and hardware arrived in sealed packaging. The stopper to the left is the fixed version that came separately and is the one I needed to use.

Seeing how simple the design of the brace is, I incorrectly assumed it would translate into a straightforward, quick install as well. Unfortunately, it proved to be more tedious than anticipated. One of the mounting bolts for the brace needed to go through a factory taped-off hole in the strut tower. The other side of the hole ended up being in quite the inconvenient location, right behind the driver side coilover’s body.

I had to remove the driver side front wheel and jack up that corner to access it, which was annoying. After poking the hole, I carefully and awkwardly maneuvered the fastener through the wheel side. The fastener IRP provided was too long for my liking, so I ended up taking it out and replacing it with one that was 5mm shorter from my personal supply.

Next, the rest of the brace assembly could be installed. I added a washer to one of the mounting points as it wasn’t provided.

In order to adjust the main bolt that attaches to the stopper, I needed to sacrifice and cut down an 8mm allen wrench to fit in the slot of the brace’s body.

The brace at least lines up decently well and the fixed-style stopper has adequate clearance in the space between the cylinder.

Although its wait time was severe, wasn’t the perfect package, and required more work than desired for the install, the brace overall is a nice addition to the car… now that it’s in. Let’s see if it really does improve the pedal feel!