Getting close! All the major parts are in, like this custom length aluminum 3.5″ driveshaft from none other than The Driveshaft Shop.

We had to place priority on getting the front and rear subframes prepared and ready for mock up in order to take the measurement for the driveshaft. I then placed the order immediately with Driveshaft Shop because the production is supposed to take 3 weeks. Conveniently, they actually finished it for me in a little over a week. Like all the other top-notch offerings from Driveshaft Shop, this one is no exception. It features a bolt-on CV joint adapter to the TR6060’s flange and then a universal joint at the 8.8 differential’s end. Incorporating a CV joint is more expensive, but features a higher range of adjustment with lower vibrations.

The fuel lines were another item on the list that needed to be measured up and then custom ordered. There will be a total of 3 “flex” lines: 2 from the gas tank to the Wix fuel filter/FPR and 1 from the fuel rail to the firewall bulkhead. The rest of the fuel system will be plumbed with a -6AN stainless steel hardline. I really wanted to overkill this area to eliminate any chance of fuel issues in the future, including fumes and having to smell gas in the garage.

I picked the XRP HS-79 hose for the lines, which is aerospace quality and incorporates smooth-bore Teflon with a Kevlar composite construction. Unlike other hoses which can be assembled at home, these have to be machine crimped. Marcus made the measurements and I gave them to XRP to pre-make. The quality of the HS-79 is certainly reflected in its pricing. This unassuming box of 3 lines was close to $400!

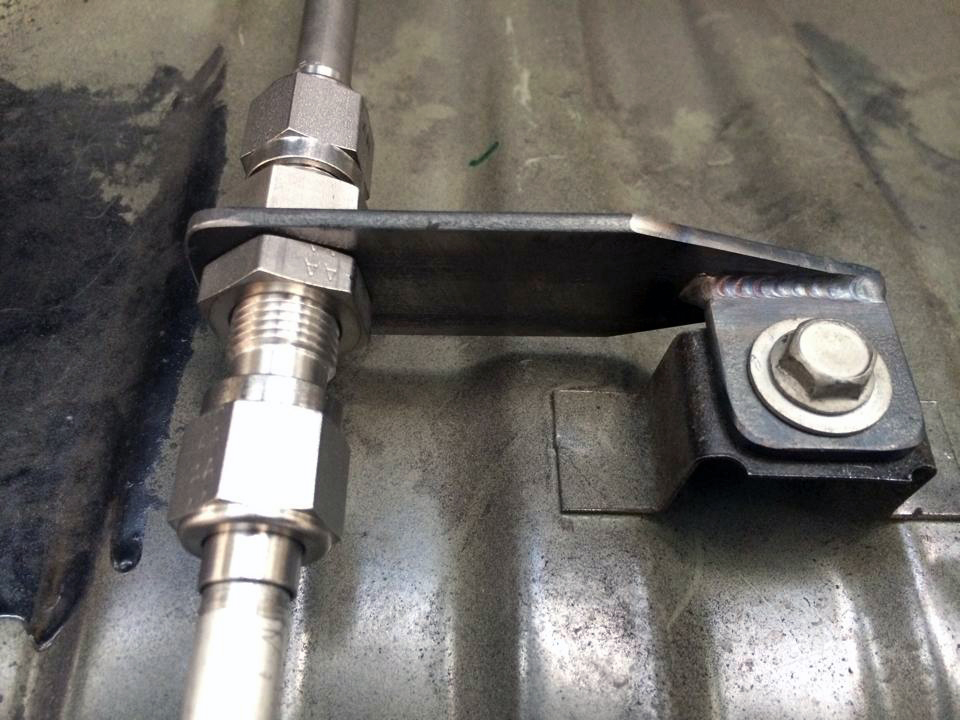

Here’s a look at the Wix filter with the stainless steel hardline routed.

Marcus made this bracket to hold the bulkhead connector for the long section of the hardline. Attention to detail – epitomized.

At the other end on the engine bay’s firewall, there is another bracket that holds together the fuel hardline and hardline for the rear brakes.

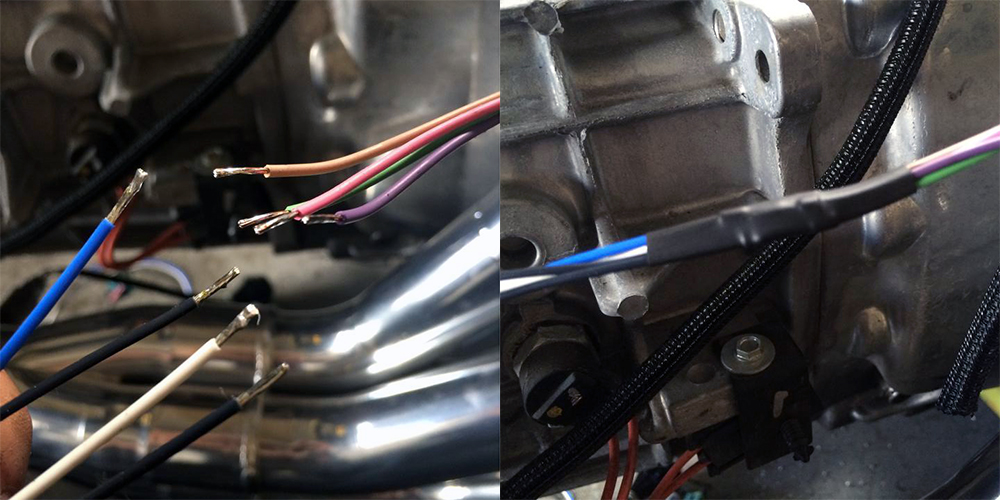

The goal is to remove redundant wires and relays from the engine bay to have a clean, tucked install. A great deal of effort is obviously required for this portion. Marcus has been working on the wiring harness over the past week. Any splices made were done properly via soldering and heat shrinking.

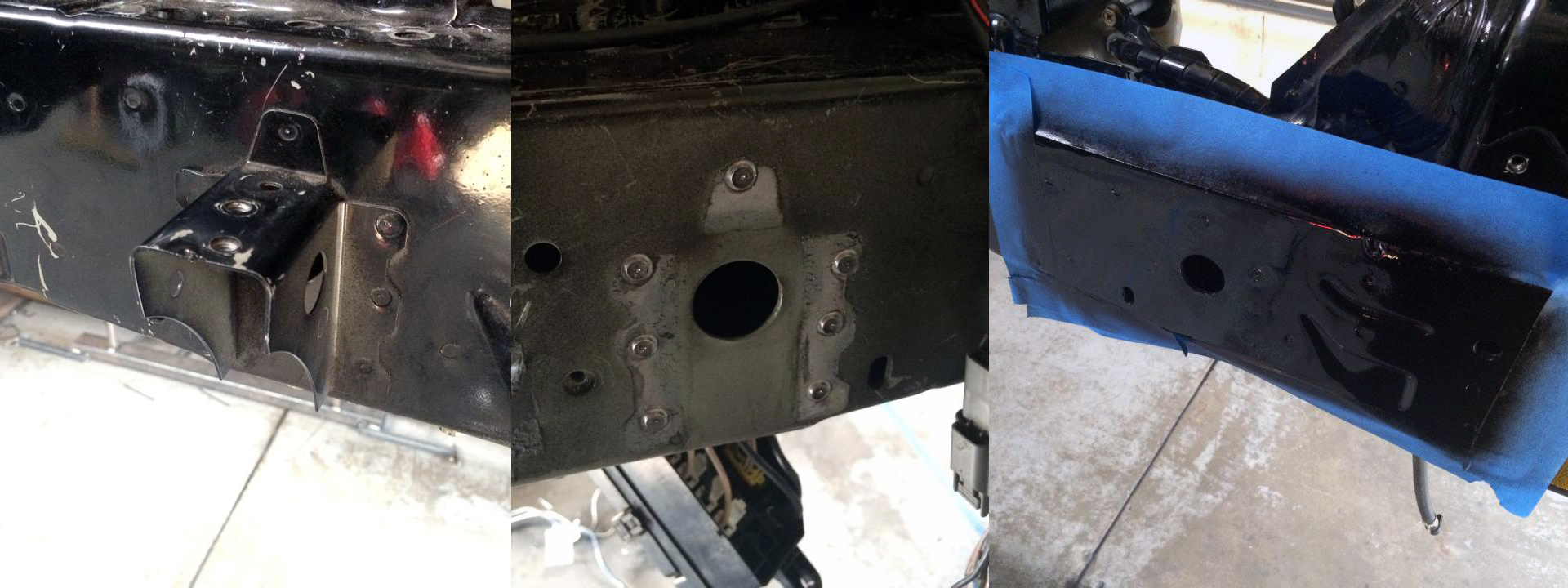

It was also determined that the spot-welded brackets which used to hold the stock radiator’s crossmember needed to be removed from the frame rails.

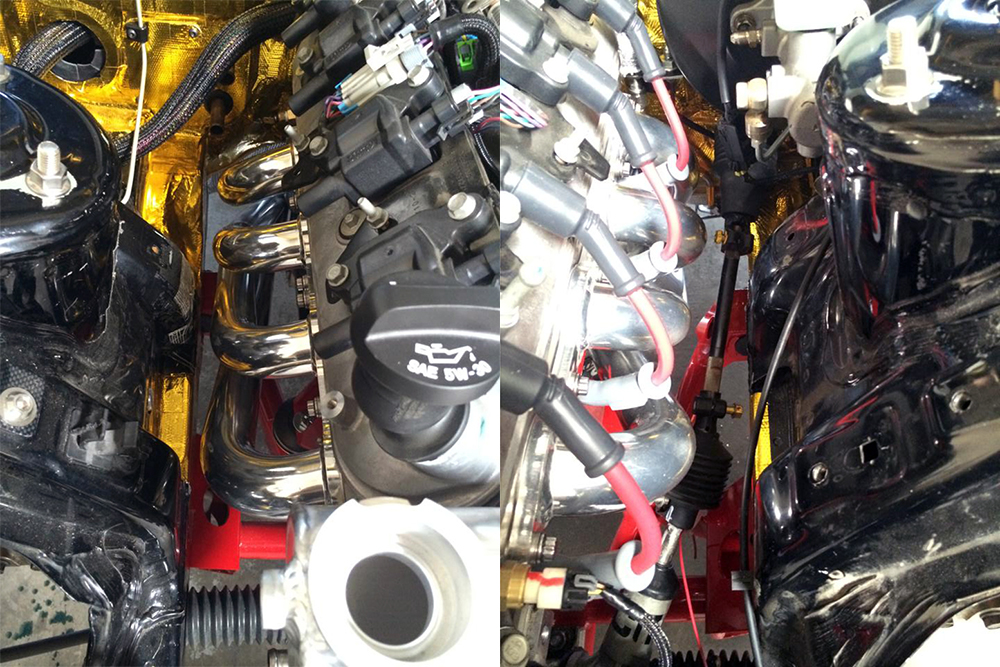

Alas, here is the engine mounted for the final time in the car.

The view from below… the Samberg components are truly superior to the factory Mazda counterparts.

The Spoolin headers have a good amount of clearance on both the passenger and driver sides.

damn, this build is inspiring… keep it up dude!

Thanks Albert!