With the rear subframe dismounted from the car to fit the new 8.8 components, Marcus took the time to weld on reinforcement plates. These were included with the Samberg kit but required additional refinement for a more perfect install.

The original plan was to use rubber/polyethylene differential mount bushings, but in the end they were discarded and a new set of bushings was lathed out of Delrin. Rubber bushings have been reported to fail under extended use with the 8.8 rearend. Using Delrin should offer a more robust solution with an indefinite lifespan.

As another showcase of detail, the Mazda fuel filter mount was offered up to the Wix filter/FPR. The ground strap from the Wix mount was tig welded on to adapt over the Mazda mount. This allows for a clean and OEM-like solution. Granted the OEM mounting location is rather high on the subframe, we are hoping accessibility can still be maintained enough to not warrant a relocation.

Samberg makes a nice, water-jetted pedal mount for the 5th Generation Camaro’s fly-by-wire pedal. The mount was painted a gloss black.

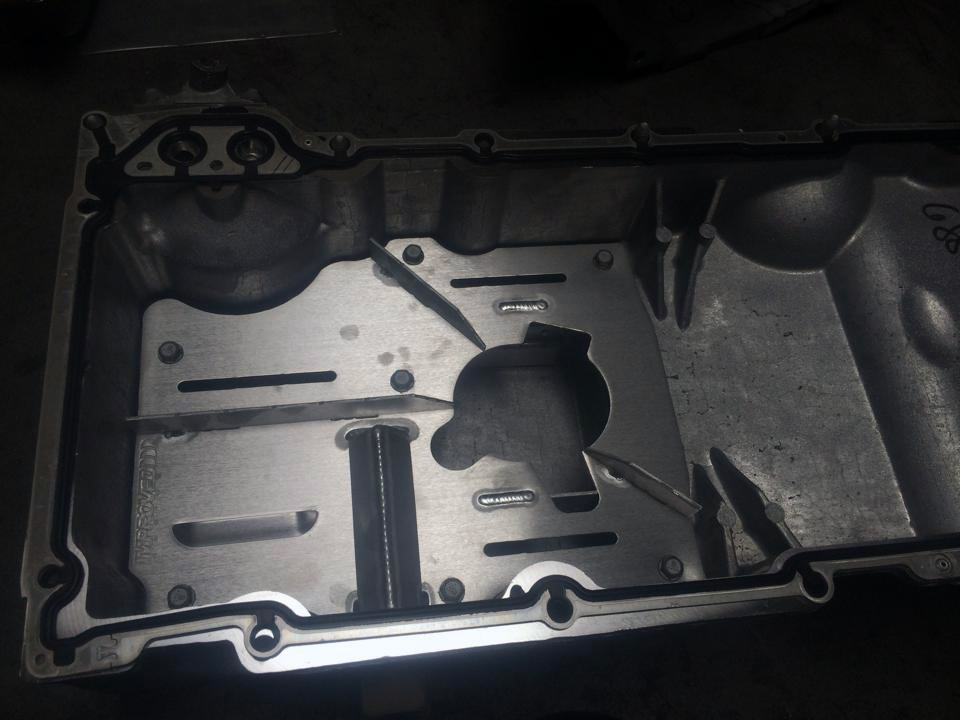

Moving up front, work was completed on the LS3 itself. The Improved Racing baffle was installed into the F-Body oil pan.

At the last minute, I was able to pick up Improved Racing’s newly released crank scraper which fits LS3 engines. This part was fresh off the manufacturer’s tooling and I had it immediately Priority mailed to the shop. As its name suggests, this plate is sandwiched between the main caps and windage tray and closely contours the crankshaft and rods – literally scraping off excess oil. The crank scraper will aid in oil control and ensures that more oil makes it to the bottom of the sump for recirculation. Having oil remain on the crank, where it is not needed, creates parasitic drag and windage losses.

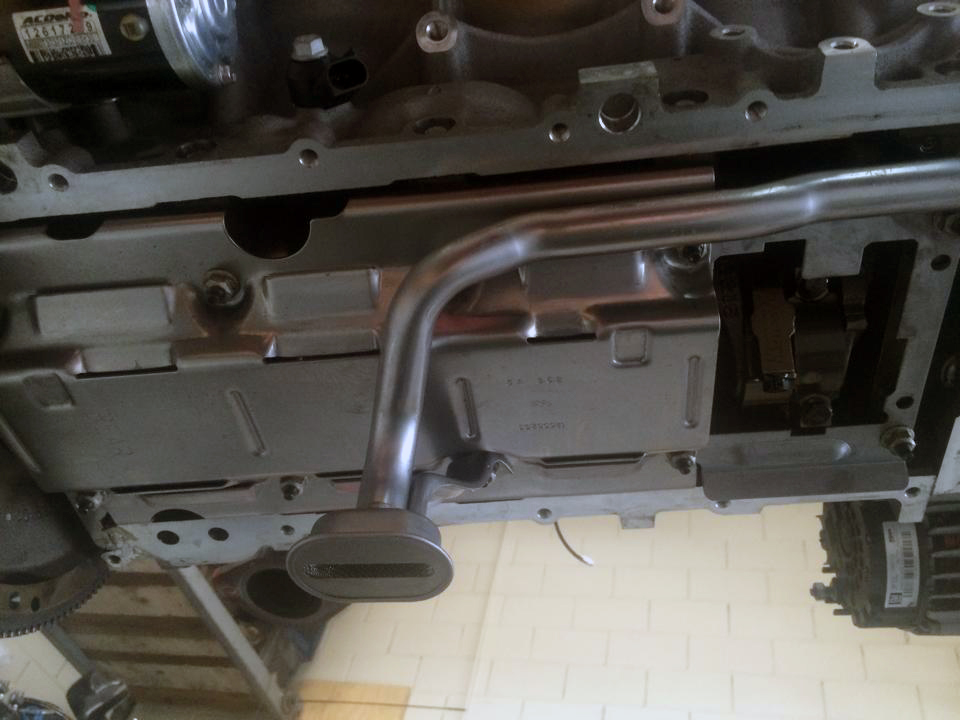

With the windage tray and pick up tube installed:

The crank scraper should be especially helpful with the F-Body oil pan because by design of its shape, oil control is minimized for the front 2 cylinders while the crank scraper can each out to them. This can be seen from the above picture – where the windage tray is only able to cover a 3/4 length.

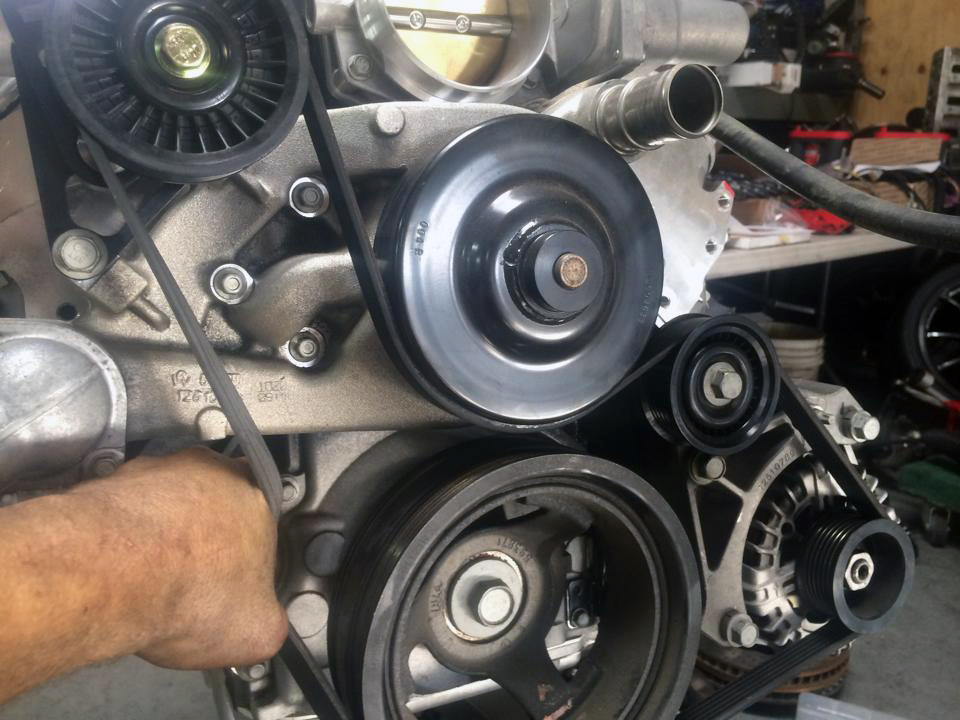

With no power steering or air conditioning, the serpentine system was greatly simplified, however, a modified idler pulley was necessary to fill in the gap. Marcus machined a spacer to push a ribbed idler pulley into the right track.

Here is what the pulley system (including the Katech tensioner pulley) looks like with a belt: