The swap is steaming along and Marcus has made a lot of headway within the first week. I asked him to take pictures for me as he went, so I could update about the project here. So here’s a rundown of the work completed thus far…

Pulling off the powerplant frame (PPF) and rear differential. I’m not a fan of the design and construction of Mazda’s PPF, it’s an inferior way to support the drivetrain and is prone to cracking under stress. The new Samberg mounts should be vastly more robust.

I will be upgrading the rear differential to the 8.8 from a Ford Cobra (’03-’04). I want the drivetrain to be bulletproof so I can hammer on it with complete disregard. It would only have been a short matter of time before the stock FD differential blows up from the increased torque levels. The 8.8 differential is BEEFY in comparison. It will add weight to the car, but at least it’s in the rear and should help balance out the also heavier LS3 up front. Here’s a picture of the 8.8 cover, which was cut and rewelded for clearance.

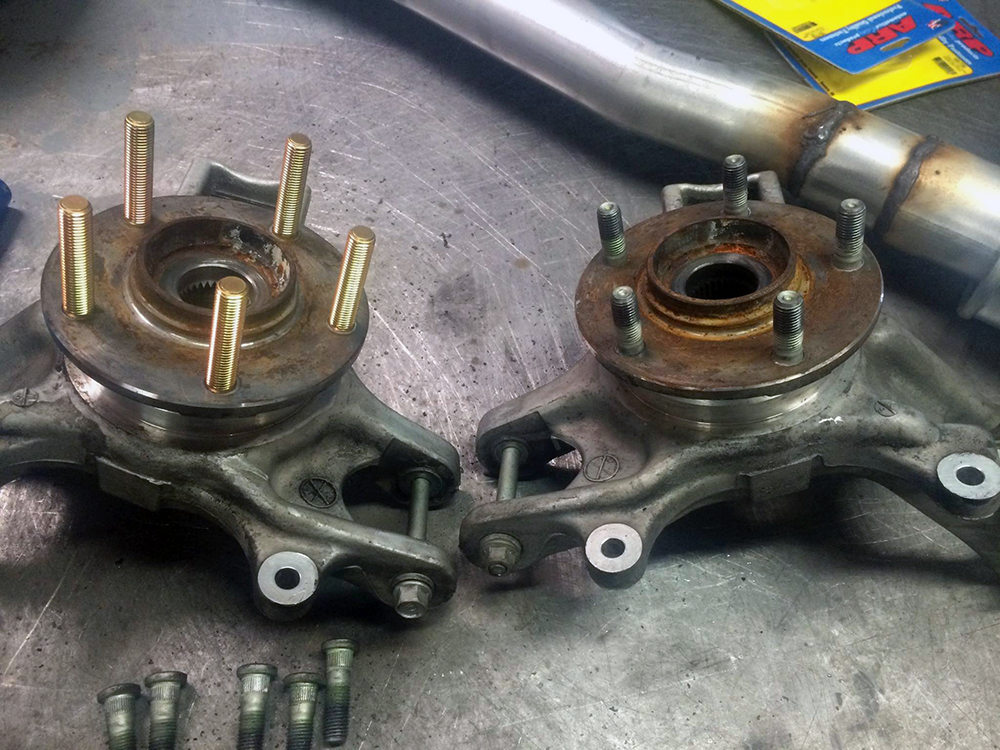

Working on assembling the new axles:

To support the increased power levels, I went with Driveshaft Shop upgraded axles with bolt-on 8.8 differential stubs. The center bars on the stock axles are made from a relatively brittle and lower grade material. These Driveshaft Shop center bars are made from heat-treated, double temper aerospace grade torsional steel with rolled splines. Fancy indeed.

With the rearend apart and the axles removed, it was a good time to pull off the hubs and install extended ARP studs. Unlike the fronts, the studs are only accessible with the hubs removed. And once the hubs are removed, the bearing is destroyed in the process and needs to be replaced. There will be a new pair of Koyo bearings going in.

A comparison of the new Bosch 044 assembly versus the old Supra Denso, stock assembly.

Since the Hyperion surge tank cover was designed for a stock-sized fuel pump, the larger Bosch 044 unit wouldn’t fit into its opening. Marcus had to do a little clearance work.

Removing the old hard lines and charcoal canister:

Dropping the fuel tank:

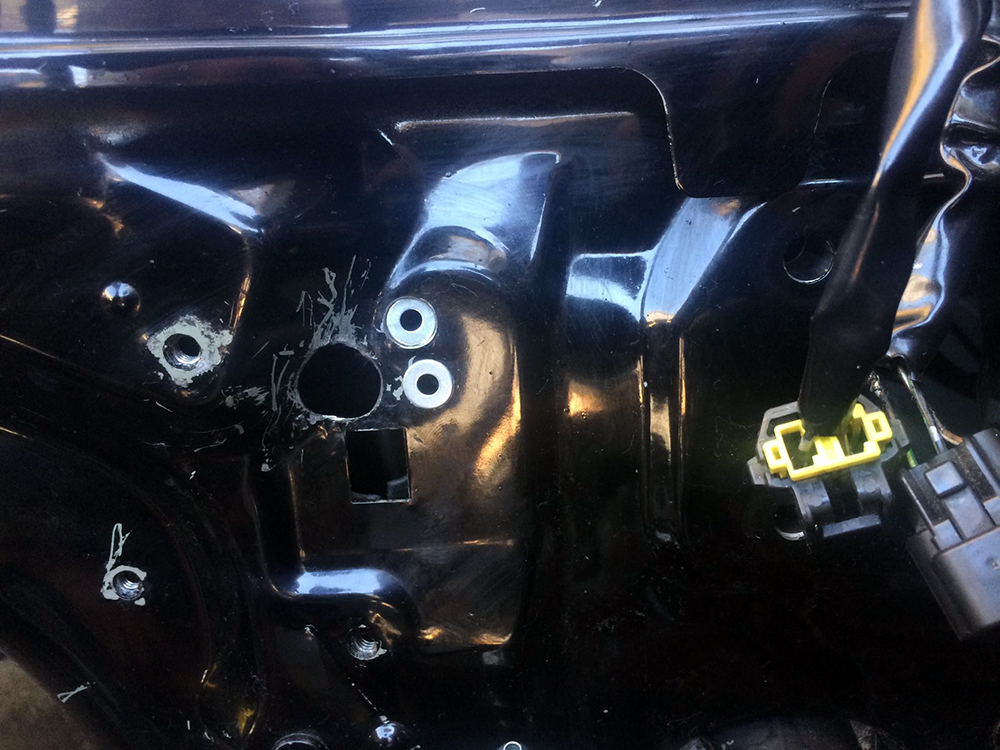

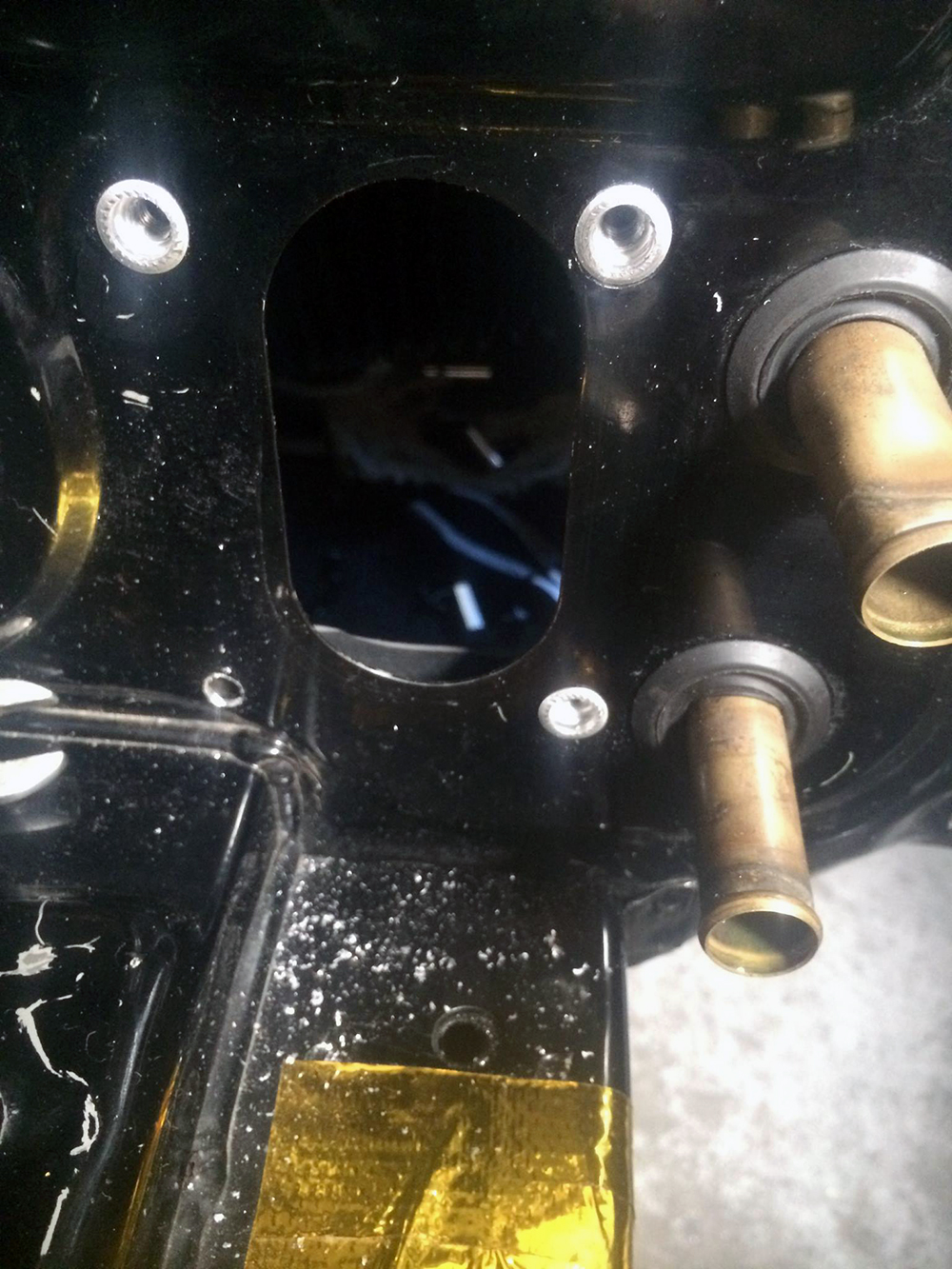

I was explicit on maintaining a high degree of attention to detail throughout the swap, and Marcus is certainly coming through in spades. For example, here are a few unsightly holes that were filled in and cleaned up:

And with the A/C removed, the liberty was taken to properly plug up the opening for the condenser lines with a plate and nutserts.

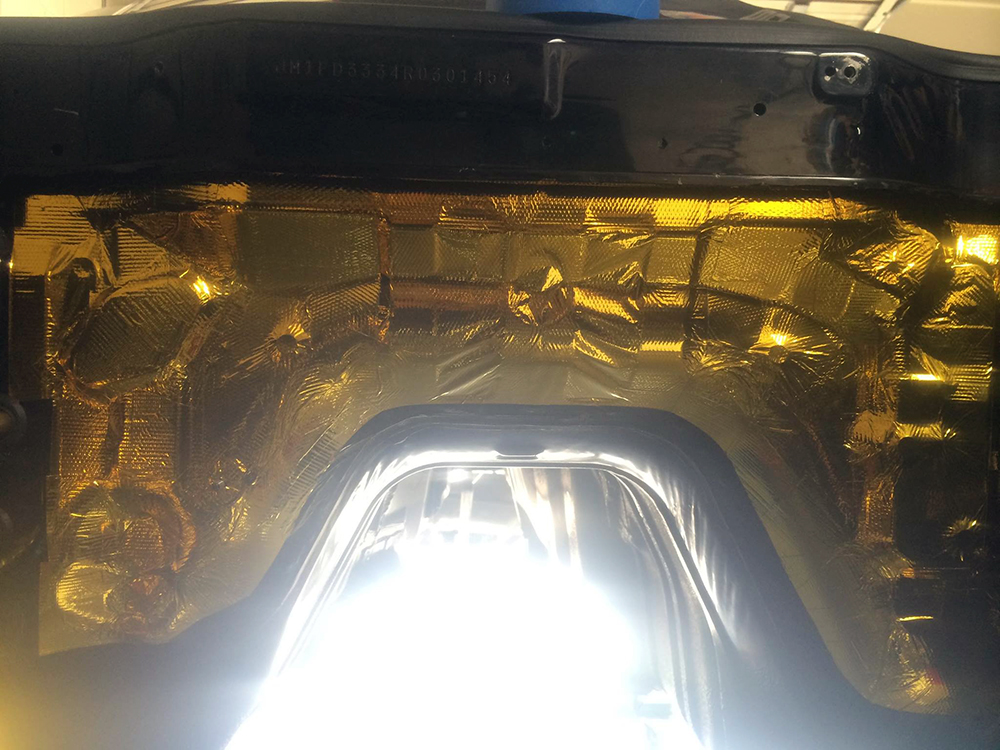

I asked Marcus to cover the engine bay abundantly with gold.

I will be ditching the old ABS Delete setup entirely in favor for double-flared hard lines with steel fittings. The hard lines will not only clean up the routing substantially, but offers functional gains over using excessive lengths of flex lines. The brake master cylinder pictured below is from a Mazda 929 and offers a larger 1″ bore, versus the stock 15/16″. The larger bore should help compensate for the increased pedal movement required to move the increased capacity of fluid in the calipers of the Brembo Big Brake Kit.

what’s torsional steel?