Included with my turbo kit was this 3.5″ stainless downpipe.

In an effort to reduce under-hood temperatures, I wanted to wrap the downpipe. I bought a roll of DEI Titanium exhaust wrap and locking ties. I’m not sure why I insisted on buying these locking ties, because I already knew from prior experience that they sucked…

The rolls only come in 15′ lengths. In combination with the 3.5″ tubing and a ~1/4″ wrapping overlap – I ran out of material roughly midway through and had to pick up a second roll.

Here is the end product.

Later when I tried installing the downpipe, it didn’t fit! I did a brief test fit in the beginning before wrapping, but that proved to be inconclusive. Once the v-band was hooked on, the other flange of the downpipe was pointing upwards at too much of an angle.

It seems like every part/component of this engine project ends up being a mini-project of its own. I unwrapped the downpipe and brought it over to FFTEC. In a very short time span, I’ve become one of their regular customers. The flange on the downpipe had to be dropped 1-3/4″ while still maintaing the same orientation and distance. The fabrication guru there was able to do all of this by simply making a measured cut and flipping around the tail section of the pipe. He left it tacked on so I could go back home to test fit before fully welding.

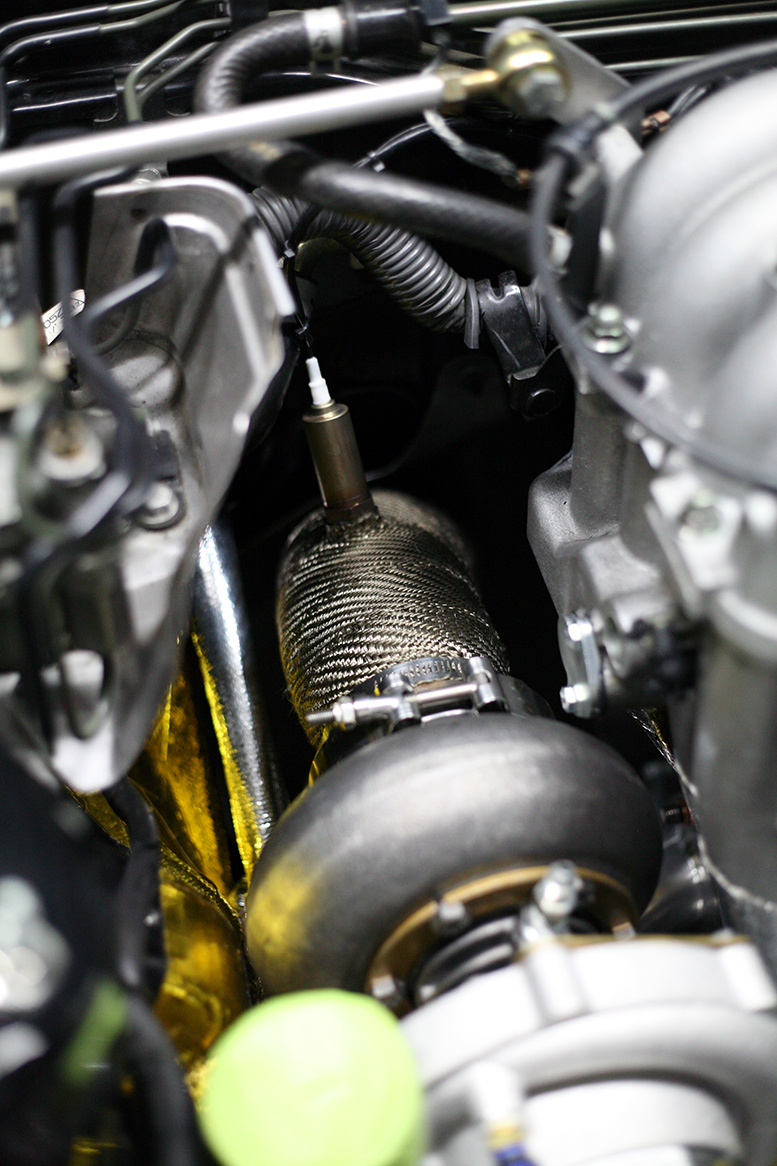

With the modification complete and the downpipe now fitting correctly, I rewrapped it again but used worm-gear clamps instead of the locking ties, which allowed me to get a much tighter wrap this time around.

Installed, plus a new Bosch O2 sensor.