In the past week, I buttoned up a few more areas that needed addressing.

Since the wheels are quite aggressively fit, the middle mounting tab on the fender flares were broken on both sides. This most likely happened when the car was tracked at Thunderhill in the past. I bought a new set of the exact same fender flares and replaced the front pair.

Not pictured, but I had the entire shifter housing and linkage assembly replaced with a refurbished set to tighten things up. Although the shifter wasn’t too radically sloppy for a 40 year old car, it could’ve been better.

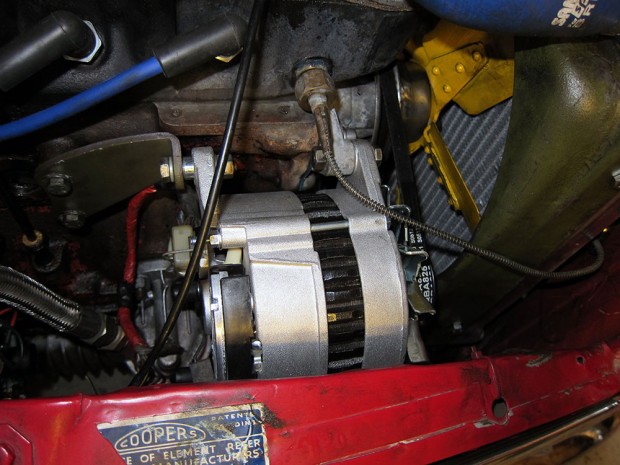

With the distributor, coil, spark plugs, and spark plug wires changed, the only thing that was left was the alternator. Not to make it feel left out, I swapped in a higher amp counterpart. With the stock alternator, the idle would drop severely when the electrical system was loaded, so hopefully the higher amps will help alleviate this to a degree.

This aluminum radiator was actually one of the first parts I bought for the Mini. It was on sale and I figured preventative maintenance never hurts, especially because the stock plastic radiators are prone to leaking anyway. On top of being all aluminum, it’s also much fatter.

The valve cover that came with the car was an awkward yellow color and had seen better days. To keep in theme with the radiator and coil, I decided to update it with a flat-top polished version. Since I had to remove the valve cover…

…it was the perfect time to adjust the valves. I set the inlet valves to .012″ and the exhaust valves to .015″. The reason why I set the exhaust valves to a slightly larger gap is to help compensate for the additional heat expansion, and it offers more buffer if there is seat recession.

Adjusting valves is a simple affair, just tedious. I threw the transmission into top gear (4th) and manually pushed the car back and forth in the garage. With the mechanical leverage of 4th gear, rolling the car around cycles the engine and allows for the valves to open and close so that they may be adjusted accordingly. It takes patience to get all the valves set just right, and the Mini’s SOHC 4-cylinder engine is about as easy as it gets. This makes me wonder how long it’d take to adjust all 64 valves in a Bugatti Veyron engine.

Last but not least… here is the new valve cover installed and sealed to top everything off.

I’ll be honest, I’ve drastically overshot my original expectations of only doing basic maintenance on this car. The car is done and drivable now, so I’m going to ease off from all the work and $$$.

so does this mean no more posts about the mini? haha jk, awesome to see all this work done. i really admire the way you approach your project “builds” and such. awesome-town.

Thanks man. Probably will be less content on the Mini…