Rotaries are a dying breed and there are not many people knowledgable in their tuning. I didn’t want to take chances and let someone inexperienced with rotaries handle such a crucial task. So I decided to get Steve Kan to do it. Although he is quite a popular and well-known rotary tuner, the catch is he lives in Texas.

In order to make this work, I had to set up a group tuning session of at least 5 people and he would fly out. Back in December around Christmas time, I made this thread on RX7Club to start gathering others for the tune. To put things into perspective, I had only just taken off the stock turbos around this time. How’s that for project management?

Obviously the actual prospective tune date was set for around late February, but nonetheless all of this needed to be done in advance. Right from the onset, I knew I didn’t want to sit around for months to years for this car to come together. In order to achieve my lofty ambitions and goals, I needed a lot of determination, copious amounts of hard work, and a bit of luck.

Eventually the tuning session filled up and we had enough people for a 2-day event. I collected the deposits and sent them over to Steve; the date was set for March 2nd-3rd. It was time to get busy.

It came quite close because I chose to redo the fuel lines and radiator fan’s mounting at the last minute. I literally finished up the fuel lines last Friday, a day before the tunes started. I was originally set to go in on Saturday, March 1st – but I moved myself to March 2nd so I could actually get the car started.

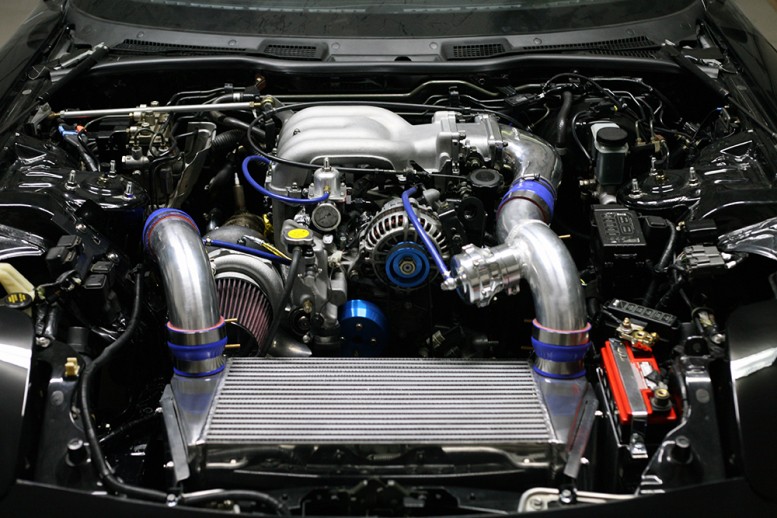

On that same Friday night, I primed the turbos and the scene was set for start-up the next morning. Come Saturday, I placed faith in my work and quality of the parts I chose… and turned the key. It fired up on the second try and was uneventful. I then set the FPR’s idle pressure to 40 psi and spent the rest of the day double checking things. Later that night, I put the stock wheels on and dropped the car back onto the ground for the first time in over 3 months. Just like that, the car was ready for its dyno tune the very next day.

My hood was still at the painter’s and I didn’t want to drive the car without a proper tune, so I coordinated with a flatbed to pick me up on Sunday morning, and then drop me back off once the tuning was over.

Steve was using Tech3 Performance’s DynoJet in San Jose.

A couple hours later, the car was tuned and ready to go! Check out the video below.

My car was easily the loudest one there that day, thanks to the twin wastegate dumps.

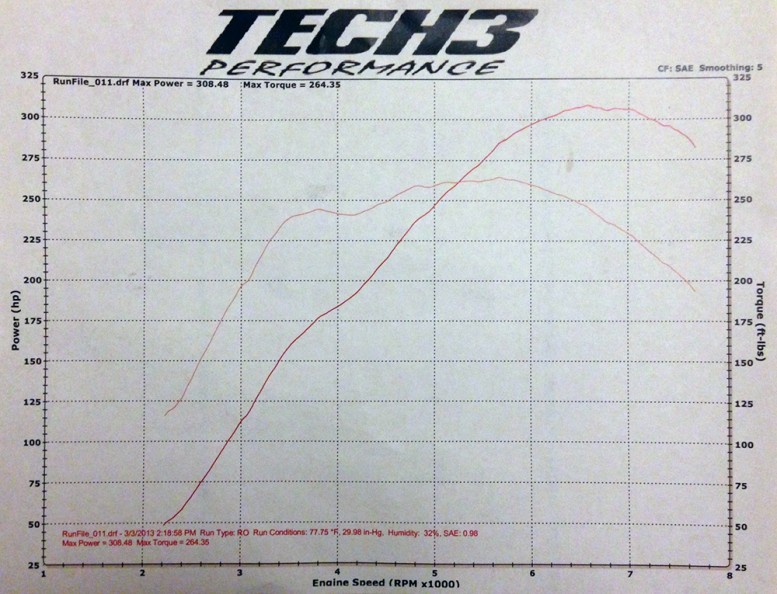

And here is my dyno graph. The car made around 310 rwhp @ 6500 RPM @ 12 psi. There was pressure drop in the high RPMS and that is reflected in the graph by the downward curve. The boost actually tapered off 1.5 psi – 2 psi, so I was essentially boosting around 10 psi after 6500 RPM.

I consulted with many experts on the subject afterwards. The pressure drop is actually inherent of running off of the wastegate springs. I routed my wastegates’ vacuum lines to the compressor housing and intercooler piping; this area gives the FASTEST response and thus opens the wastegates sooner. I’m basically experiencing reverse creep. One option is to route the vacuum lines post-intercooler to inhibit a delay in the response, and gain back the pressure drop. Another is to install a boost controller. This is also where a street port can also come into play, because then the power would continue to climb for longer.

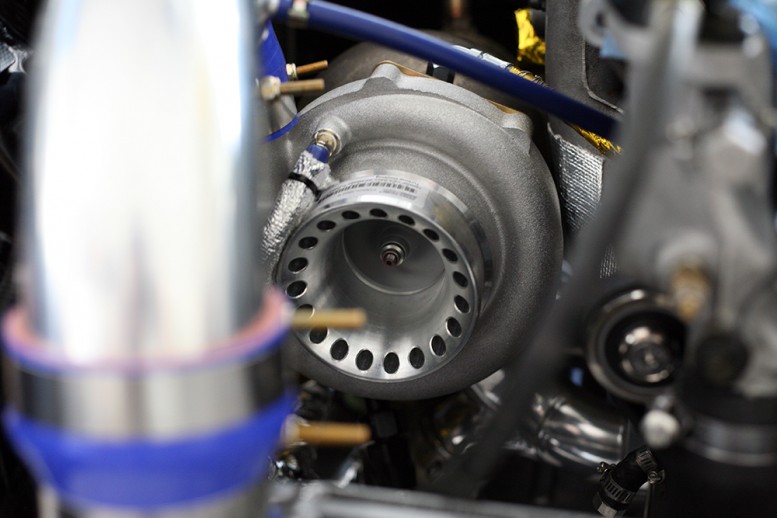

I’m going to do neither because I’m happy with the setup as is, and I like the reduced complexity and mechanical simplicity of running only wastegate springs. Many racers configure their turbo systems in the same manner to purposely achieve pressure drop at high RPMs, because in a race or track setting, lower boost at higher RPMs equals better reliability. Peak horsepower is only a number. Sure, I would have liked 350 rwhp, but that’s just getting greedy. The 5866 is still a relatively small turbo, don’t be fooled by its large frame size, so low to mid 300’s is within range @ 12 psi.

At the end of the day, I was tired from all the anxiety but mostly felt relief. I didn’t even feel that much excitement, to be honest. I mean, when you’re done with a build of such magnitude, you have to set your expectations high, it would be counter intuitive otherwise. Anything less than a fully working car would be failure.

Alas, over 3 months of work is funneled into one weekend. I admit, I am quite awed now at the fact that the car was started for the first time just a day before the tune. This just goes to show that the best way to accomplish a task is to have full confidence and commitment.

“If you want to take the island, then burn your boats. With absolute commitment come the insights that create real victory.” – Tony Robbins

Hey my friend David works at Tech3! Keep up the posts eric, i love reading it

Thanks Jackson! How’s your FD coming along?

Quite stock and low mileage still! I like having it stock besides that diffuser and downpipe… I never liked throwing in parts without having a good reason to do so. I like your rants! I agree with a lot of your justifications and ideals as to why/why you don’t do certain things. Maybe one day I’ll run into you in real life, we don’t live too far apart!

For sure, say hello if we ever cross paths! I was talking to a couple other FD guys today and we’re thinking about doing a little BBQ soon, you should keep an eye out for that ;-)

Awesome, glad it worked out. Sorry if I was a factor as to why you settled with Steve Kan instead. But what’s done is done and it definitely came out pretty well. Good call on that “reverse boost creep” too.

Thanks Kent, I was actually just doing research on future tunes down in SoCal. A tune is like a maintenance item, gotta keep it updated ;-)