When dealing with a large project, it can be hard to slow down and focus on the little things, but everything matters; down to each fastener. This is why I like to do my own work, the level of control is unrivaled. I simply don’t think even paying a shop can yield better results in this respect.

If I’m trying to buy a car, the first thing I examine and attempt to construe is the maintenance history and who did the work. If the car was modified, then this point becomes compounded and is especially crucial. If I see that some kid in his teens or early twenties did everything at home, that’s an immediate red flag and I will run for the hills. On the other hand, I would probably buy a car from myself – or at least my mindset is geared towards this intention.

The most ideal candidate for a previous owner is someone who has a combination of neuroticism and experience. It’s safe to say that I can get extremely OCD with my cars. And looking back, I haven’t put down the wrench for even one year since I was 16… I was always working on something, whether it was a car or a bike. It’s this experience that has lead me to where I am today with the RX-7.

What I’m trying to rationalize here is that there should be a high level of detail and workmanship manifested throughout a build or project. This is the goal, but the question is, how many people and cars out there actually hit the mark? Very few… Those that do fall into the category should be regarded differently and you’re more likely to find a worthwhile product here. Everything else simply becomes average.

Ranting aside, I’d like to showcase a few items of interest.

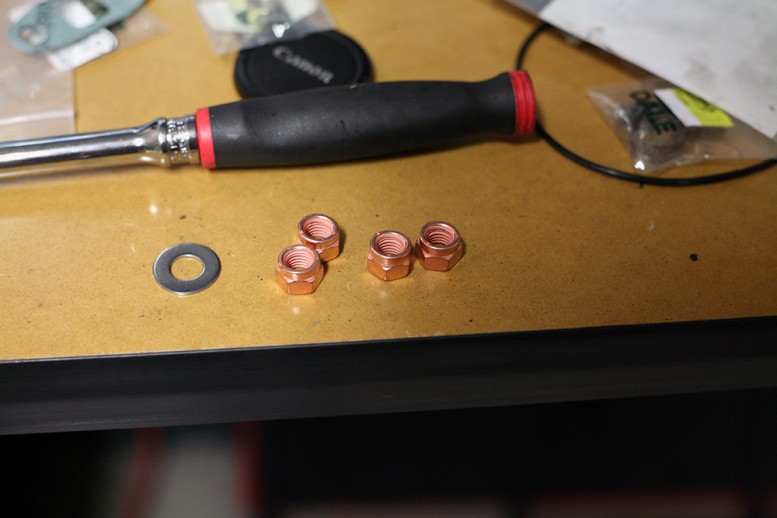

For the manifold studs, instead of reusing the stock nuts that bite into the threads, I opted for these copper locking nuts. I’m also using these locking nuts on the exhaust flanges. The hex of the nuts is 14mm, a convenient trait, albeit with so many USA made parts on the car it becomes a futile battle to keep everything synchronized with metric sizes.

Accompanying the copper locking nuts, I used a touch of super high temperature anti-seize to fend off corrosion and aid in removal. This stuff can withstand temperatures up to 3000* Fahrenheit.

Zip ties, although frequently used, tend to be overlooked. I decided to step up the quality of zip ties I used from generic brands to Thomas & Betts. These have a stainless steel locking prong and gain a higher tensile strength – I highly recommend them.

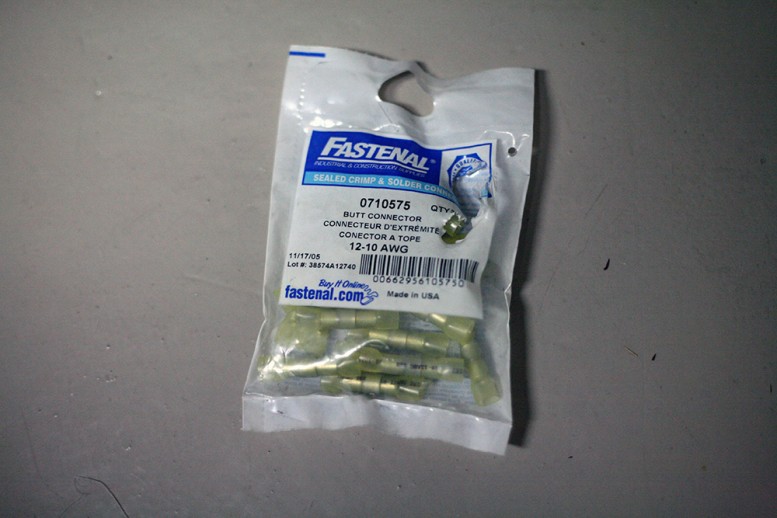

The subject of splicing electrical wires together in an automotive environment is a debated one: solder or crimp? Soldering, when done right, is great for establishing a connection with low resistance. However, it is brittle and can be prone to fracturing from vibrations, thus giving the crimping an edge in versatility.

After weighing the pros and cons of both methods, I ended up choosing to combine BOTH. I made a trip to a local Fastenal and picked up these sealed crimp and solder connectors. They’re expensive, but allow you to first crimp together two wires and then flow in solder by heating the center section. Best of both worlds. I used these connectors for the fuel pump rewire and to extend the radiator fan’s wiring.

I drained the gas tank in order to introduce fresh ’91 Chevron and start the premix diet anew. Mazda actually included a drain plug at the bottom of the gas tank, how cool is that. All it takes is a 17mm wrench and you’re done… no need to mess with siphons or anything silly. I also flushed the old coolant that was in the block to start flushing the coolant system.

When it was time to seal the gas tank and block back up, I bought new bolts and crush washers from Mazda to complete the job.

Left to right: gas tank; center iron (coolant); differential fill and drain plugs; and a pair of new crush washers for the oil pan. The last 3 items are for future use.

One thought on “Attention to Details”