The A-Spec turbo kit fit together within expectations. There were a few minor items that needed modification, namely the downpipe (discussed further in a later post). More focally, however, the crucial parts of the system went together like a fine watch’s clockwork and this alone appeased the long wait-time and price for me. When dealing with a niche car and handmade fabrications, there is a degree of leniency you have to uphold.

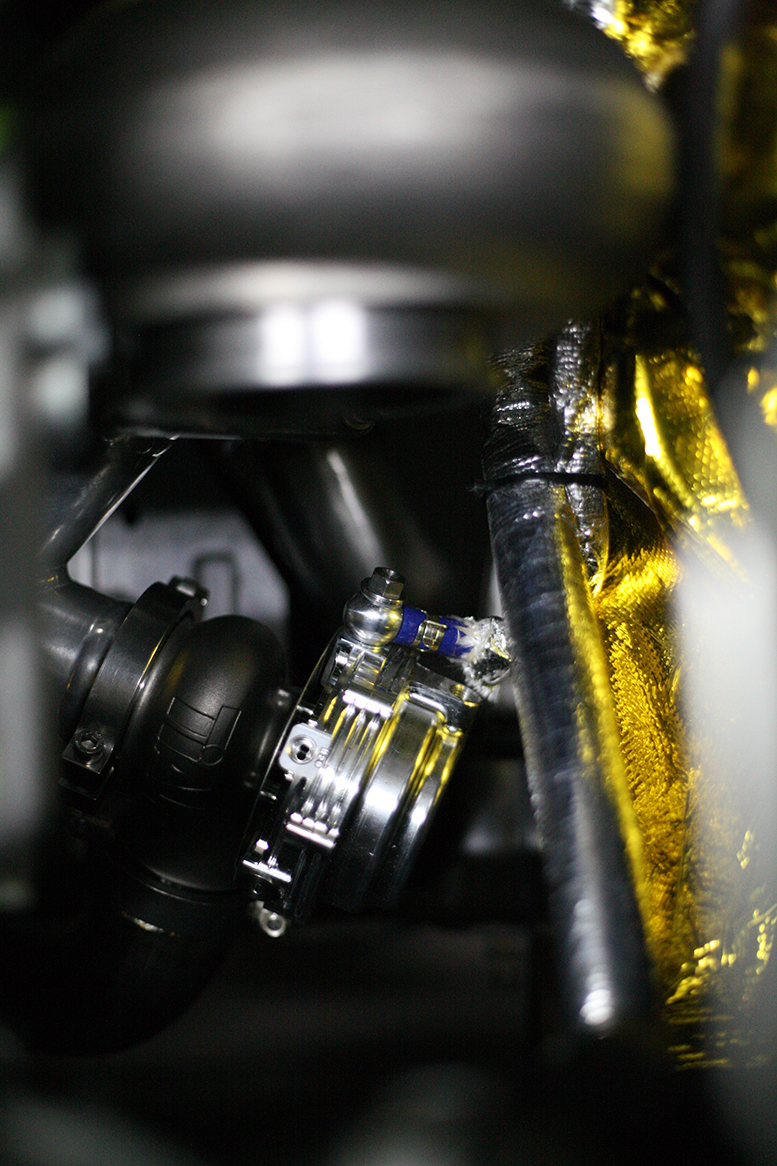

Here is everything all mounted up in the engine bay. The 5866 turbo is physically quite large. The clearance between the car body and LIM is tight, but just right. A-Spec did a spot-on job with this part, and it’s arguably the most critical. The short-runner design of the manifold sits the turbo low and relatively far back. This leaves ample room in the front, where a 5″+ air filter can be used.

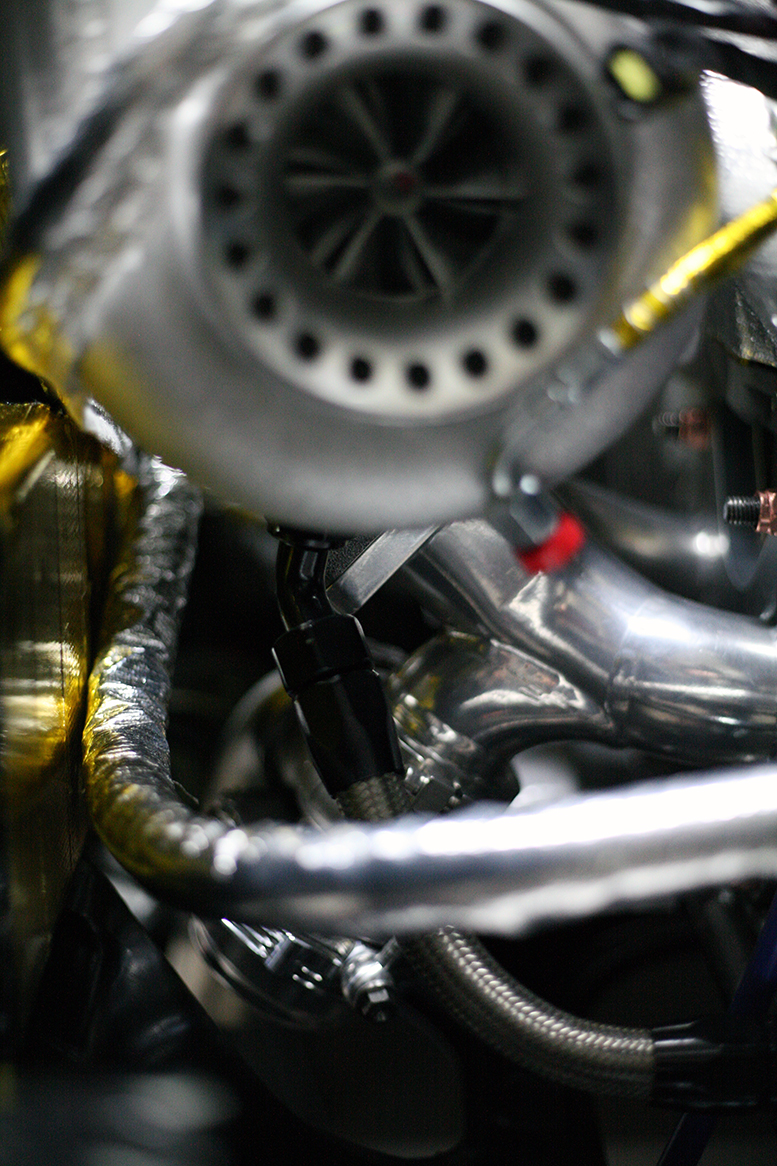

And a closer look at the manifold & wastegates. I made sure to be thorough and invested in reflective heat sleeves to keep hoses in the area safe.

These are the dump pipes aimed and mounted. This party is about to get REAL loud.

In the picture above, with the pipe coming through the hole in the subframe near the control arm, you can see the 4″ extension I had to get welded on.

All this hardware is making the engine bay mesmerizing… occasionally, in between work, I find myself just standing and staring at everything for extended lengths of time.