Doing basic wiring work is pretty fun in my opinion. You could get away with connecting two wires together with a crimp connector, but that’s boring. Which is why I prefer to solder wires and finish them off with heat shrink. Way more legit.

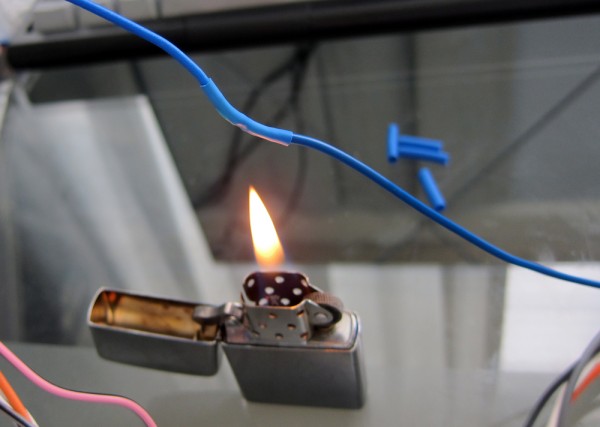

So here are my tools of the trade: wire stripper, heat shrink tubing, zippo for heat shrink, rosin core solder, and iron. I was using a Radio Shack soldering iron for the longest time… the tip was coming loose and it was totally oxidized black. Luckily, I found a handy Sears gift card in a drawer and bought a new iron and holder to replace it :-)

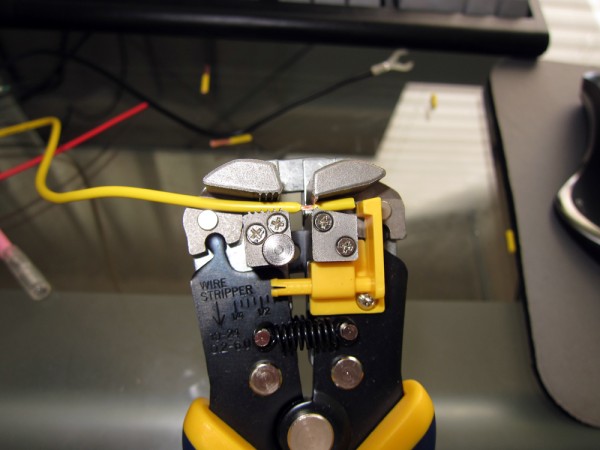

The real star of the show is the wire stripper… My primary method of stripping wires, up until now, has been all manual – with the scissors from my swiss army knife. I decided to step things way up and picked up this Irwin Vise Grip Self Adjusting wire stripper:

Great buy… it makes the once tedious task of stripping wires almost humorously effortless. There’s another option out there called the Quik Strip, but in all honesty, it pales in comparison to the quality and functionality of the Vise Grip brand wire stripper. For one, the Vise Grip is a mostly metal construction, and the “jaws” are even replaceable should they need to be.

You simply put the wire in against the yellow plastic stopper, which can be moved back and forth accordingly, and squeeze the grips. Done!

If you plan on doing any sort of electrical work, I recommend picking up this tool. It will save you a ton of time and provide years of use. Works on the majority of wires, from 10 gauge down to 24. Look around, you can pick one up for around $20-30.

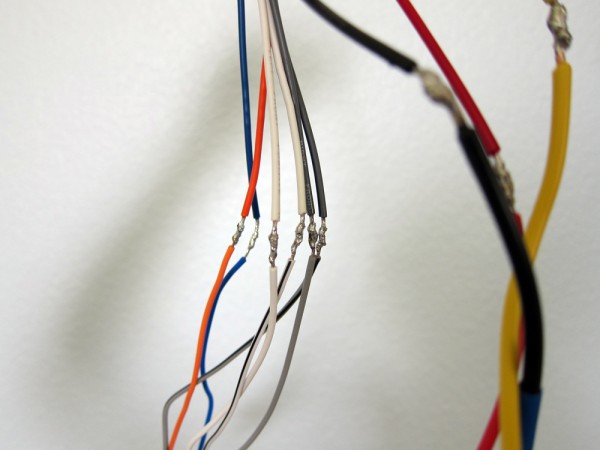

Anyway, with the wires all nicely stripped, it was time to twist them together and try out the soldering iron. I’m sure soldering is common knowledge now, but I’ll talk about it for the sake of talking about it. I always tin the tip and then touch it onto the joint being made. After holding the tip there for a few moments to let the joint heat up, the solder can then be fed in. Applying the solder to the tip of the iron, and letting it “drip” onto the wires is a no-no.

I then heated up some shrink tubing to finish it all off. I just used a lighter for this, does the job. Obviously, the tubing goes on before twisting the wires together… it’s a big face palm moment when everything is soldered up and you forget to put the tubing on first.

Nice post bro. This reminds me of me and my Studio Maintenance class for school. Currently trying to learn how to prep XLR, instrument, TRS (tip-ring-sleeve) cables. I gotta get myself that wire stripping tool like yours. I had TOO many cases of making an attempt to strip the wire and ending up cutting off a wire in the process. Of course, I’d have to cut the wire short again and redo it since not all the wires are of the same length allowing the proper current flow through them. I gotta practice soldering too cuz putting wires into a pot with solder for the connectors is quite challenging. =P